Sandblasting Near Me for Dummies

Wiki Article

The Greatest Guide To Sandblasting Near Me

Table of ContentsThe Greatest Guide To Sandblasting Near MeThe smart Trick of Sandblasting Near Me That Nobody is Talking AboutThe Best Strategy To Use For Sandblasting Near MeThe smart Trick of Sandblasting Near Me That Nobody is DiscussingSandblasting Near Me Can Be Fun For AnyoneFascination About Sandblasting Near MeThe Only Guide to Sandblasting Near Me5 Easy Facts About Sandblasting Near Me Explained

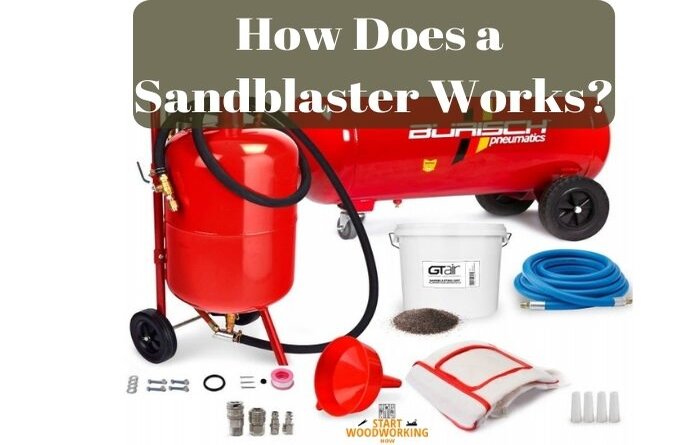

Sandblasting a stone wall Diesel powered compressor made use of as an air supply for sandblasting Unpleasant blowing up, extra frequently called sandblasting, is the procedure of by force moving a stream of abrasive material versus a surface area under high stress to smooth a harsh surface area, roughen a smooth surface area, shape a surface or eliminate surface impurities. Sandblasting devices generally is composed of a chamber in which sand and also air are mixed. The mix takes a trip with a hand-held nozzle to guide the bits towards the surface or work piece. Nozzles come in a selection of forms, dimensions, as well as materials.Damp rough blowing up [modify] Wet unpleasant blowing up usages water as the liquid moving the abrasives. The advantages are that the water catches the dirt generated, and lubricates the surface. The water supports the effect on the surface, minimizing the elimination of sound product. Among the initial pioneers of the damp unpleasant process was Norman Ashworth that located the benefits of making use of a damp procedure as a solid option to completely dry blowing up.

The Sandblasting Near Me Statements

A variant of damp blowing up is vapor blasting (or vapour blasting; U.K.). In this process pressurized air is added to the water in the nozzle generating a high rate mist, called "vapor". This procedure is also milder than wet blowing up, permitting mating surfaces to be cleansed while keeping their ability to mate.

Our Sandblasting Near Me Ideas

Blending bits with water substantially reduces dust. Grain blasting is the process of eliminating surface deposits by using great glass beads at a high pressure without harming the surface. It is utilized to tidy calcium down payments from pool ceramic tiles or any other surface areas, get rid of embedded fungus, and also brighten grout color.In getting rid of paint for auto body work, bead blasting is chosen over sand blasting, as sand blasting tends to produce a higher surface profile than bead blasting. Bead blasting is typically utilized in producing an uniform surface finish on machined components.

The 7-Minute Rule for Sandblasting Near Me

The initial blast wheel was patented by Wheelabrator in 1932. In China, the first blast wheel was developed around the 1950s, Qinggong Machinery is one of the earliest suppliers of blast wheel. Hydro-blasting [modify] Hydro blasting is not a form of unpleasant blasting as no unpleasant media is utilized. Hydro-blasting, typically called water blasting, is frequently utilized because it normally requires just one operator.This method is excellent check this site out for cleaning up inner and exterior surfaces since the driver is typically able to send out the stream of water right into places that are tough to reach utilizing various other methods. One more advantage of hydro-blasting is the ability to recapture and also reuse the water, decreasing waste and also mitigating environmental effect.

All about Sandblasting Near Me

Greater stress are frequently needed. One of the most typical micro-abrasive blasting systems are business bench-mounted devices being composed of a power supply and also mixer, exhaust hood, nozzle, and also gas supply. The nozzle can be hand-held or component placed for automatic procedure. Either the nozzle or component can be relocated in automated procedure.

Fascination About Sandblasting Near Me

Others are receptacle-fed types making them lightweight and also much more mobile. In damp blasting, the abrasive is introduced right into a pressurized stream of water or other fluid, creating a slurry. Damp blasting is usually utilized in applications where the minimal dirt generation is desired. Mobile applications might or may not reuse the abrasive.

Not known Facts About Sandblasting Near Me

It usually contains four elements; the control (closet), the abrasive blasting system, the rough recycling system as well as the dirt collection. The driver blasts the components from the beyond the cabinet by placing his arms in gloves affixed to handwear cover openings on the cupboard, watching the component via a view home window, transforming the blast on and also off making use of a foot pedal or treadle.There are 3 systems generally made use of in a blast closet. 2, view website siphon and pressure, are dry as well as one is wet: A siphon blast system (suction blast system) utilizes the compressed air to create vacuum in a chamber (called the blast gun). The negative pressure draws unpleasant right into the blast weapon where the pressed air guides the abrasive with a blast nozzle.

Not known Factual Statements About Sandblasting Near Me

Nozzles can be found in a selection of shapes, dimensions, as well as materials. Tungsten carbide is the lining material most typically used for mineral abrasives. Silicon carbide and also boron carbide nozzles are a lot more put content on immune and also are frequently utilized with tougher abrasives such as aluminium oxide. Economical rough blowing up systems as well as smaller cupboards use ceramic nozzles.The vessel is pressurized to the same stress as the blast hose affixed to the bottom of the stress vessel. The unpleasant is metered into the blast tube and shared by the compressed gas with the blast nozzle. Damp blast cabinets utilize a system that infuses the abrasive/liquid slurry into a pressed gas stream.

Report this wiki page