Examine This Report on Sandblasting Near Me

Wiki Article

The Buzz on Sandblasting Near Me

Table of ContentsThe Basic Principles Of Sandblasting Near Me Sandblasting Near Me for DummiesGet This Report about Sandblasting Near MeSandblasting Near Me Fundamentals ExplainedRumored Buzz on Sandblasting Near MeThe Greatest Guide To Sandblasting Near MeGet This Report on Sandblasting Near MeSandblasting Near Me Can Be Fun For Anyone

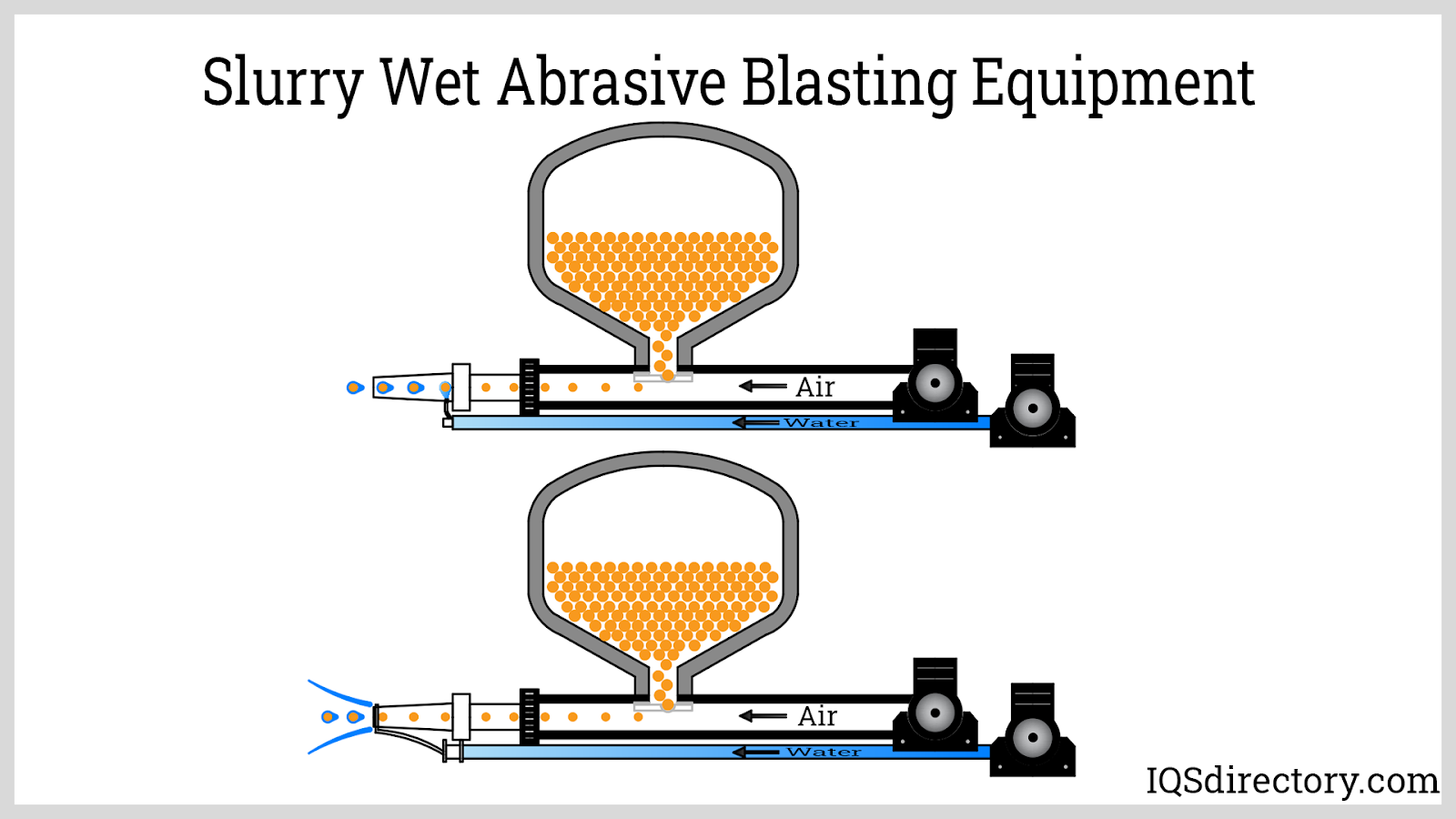

Sandblasting tools generally consists of a chamber in which sand as well as air are blended. The combination takes a trip via a hand-held nozzle to route the bits towards the surface or job piece. Nozzles come in a selection of forms, dimensions, and products.Damp abrasive blowing up [modify] Wet rough blowing up uses water as the liquid relocating the abrasives. The benefits are that the water catches the dirt produced, and lubes the surface. The water cushions the impact on the surface area, lowering the removal of sound material. One of the original leaders of the wet abrasive procedure was Norman Ashworth who discovered the benefits of utilizing a damp procedure as a strong option to dry blasting.

The Basic Principles Of Sandblasting Near Me

A version of wet blowing up is vapor blasting (or vapour blasting; U.K.). In this process pressurized air is added to the water in the nozzle creating a high rate mist, called "vapor". This procedure is even milder than damp blasting, permitting mating surfaces to be cleaned up while preserving their capacity to mate.

Indicators on Sandblasting Near Me You Need To Know

Mixing particles with water significantly lowers dust. Bead blasting is the procedure of eliminating surface down payments by applying great glass grains at a high stress without harming the surface.In getting rid of paint for car body job, grain blasting is chosen over sand blasting, as sand blowing up often tends to create a higher surface profile than bead blasting. Grain blasting is often used in producing a consistent surface coating on machined components.

Sandblasting Near Me Fundamentals Explained

The very first blast wheel was patented by Wheelabrator in 1932. Hydro blasting is not a type of rough blasting as no unpleasant media is used. Hydro-blasting, generally understood as water blasting, is generally used due to the fact that it normally needs only one driver.This approach is optimal for cleansing interior and external surfaces due to the fact that the driver is usually able to send out the stream of water into places that are challenging to reach making use of other approaches. An additional benefit of hydro-blasting is the capability to regain as well as reuse the water, decreasing waste and mitigating ecological impact.

The Single Strategy To Use For Sandblasting Near Me

Greater stress are commonly called for. The most typical micro-abrasive blasting systems are business bench-mounted devices containing a power supply and mixer, exhaust hood, nozzle, and also gas supply. The nozzle can be hand-held or fixture installed for automated operation. Either the click this site nozzle or part can be relocated automatic procedure.

The Greatest Guide To Sandblasting Near Me

Others learn this here now are receptacle-fed kinds making them light-weight and a lot more mobile. In wet blowing up, the abrasive is presented into a pressurized stream of water or other liquid, creating a slurry. Damp blasting is frequently used in applications where the marginal dust generation is preferred. Portable applications may or may not reuse the rough.

The Greatest Guide To Sandblasting Near Me

It usually contains 4 parts; the containment (closet), the unpleasant blasting system, the abrasive recycling system and also the dust collection. The operator blasts the parts from the beyond the cabinet by putting his arms in gloves affixed to handwear cover openings on the cupboard, watching the part with a view home window, turning the blast on and off click for info utilizing a foot pedal or treadle.There are 3 systems typically utilized in a blast cabinet. Two, siphon and also stress, are dry as well as one is damp: A siphon blast system (suction blast system) utilizes the compressed air to produce vacuum in a chamber (called the blast gun). The negative pressure pulls rough into the blast gun where the compressed air guides the abrasive through a blast nozzle.

The smart Trick of Sandblasting Near Me That Nobody is Talking About

Nozzles are available in a selection of shapes, dimensions, and also products. Tungsten carbide is the liner material frequently used for mineral abrasives. Silicon carbide and also boron carbide nozzles are much more use immune as well as are typically made use of with tougher abrasives such as aluminium oxide. Cost-effective abrasive blowing up systems and also smaller cabinets use ceramic nozzles.The vessel is pressurized to the exact same stress as the blast tube connected to the bottom of the pressure vessel. The rough is metered right into the blast tube and shared by the compressed gas with the blast nozzle. Wet blast closets make use of a system that injects the abrasive/liquid slurry right into a pressed gas stream.

Report this wiki page